Enhancing Transformer Life Expectancy With Transformer Oil Purification Methods

Enhancing Transformer Life Expectancy With Transformer Oil Purification Methods

Blog Article

Safeguard the Environment With Trusted Transformer Oil Recycling Provider

The importance of transformer oil recycling can not be overemphasized, particularly in the context of environmental preservation. The concern stays: how can companies properly choose a recycling service provider that straightens with their environmental objectives?

Importance of Transformer Oil Recycling

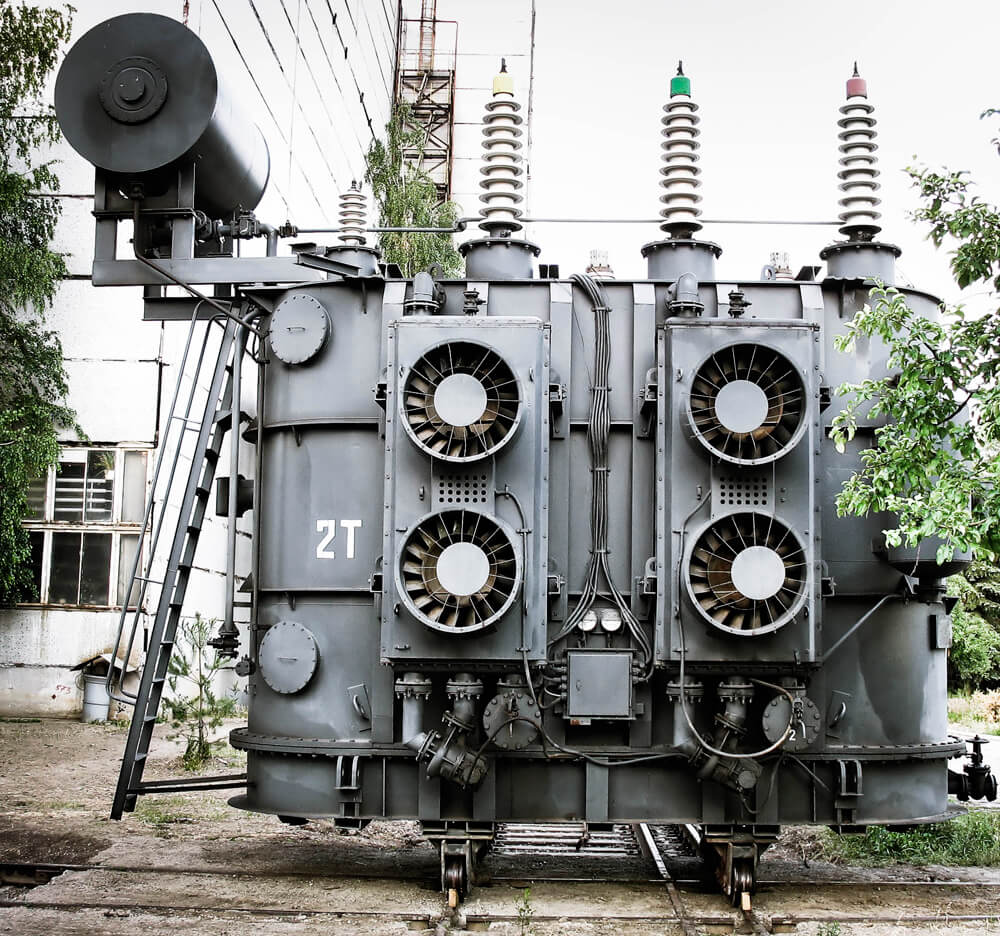

Transformer oil recycling is significantly acknowledged as a vital method in the management of electric infrastructure. Making use of transformer oil, crucial for cooling down and shielding electric transformers, brings about the buildup of waste oil that necessitates responsible handling. Reusing this oil not just saves important all-natural sources but also plays a pivotal function in promoting sustainability within the power industry.

Additionally, transformer oil recycling can substantially decrease functional costs for businesses and energies. By recycling oil, organizations can minimize expenditures connected with purchasing new oil and handling garbage disposal. Implementing reliable recycling programs reflects a commitment to ecological stewardship and operational performance, positioning companies as leaders in lasting methods within the electric industry. Generally, the value of transformer oil recycling can not be overemphasized as it sustains both ecological and financial goals.

Ecological Effect of Improper Disposal

The inappropriate disposal of transformer oil postures considerable environmental threats that can not be neglected. Transformer oil often includes unsafe substances, including polychlorinated biphenyls (PCBs), which can contaminate dirt and water resources if released right into the environment. When poorly disposed of, these hazardous chemicals can seep into groundwater, positioning serious health dangers to local communities and communities.

In addition, transformer oil can disrupt water environments when it gets in bodies of water, bring about damaging impacts on fish and various other wildlife. The oil creates a film on the water surface area, limiting oxygen exchange and impeding photosynthesis in water plants. Furthermore, the determination of these pollutants in the environment can cause bioaccumulation in the food cycle, influencing not just wild animals yet also human health with the intake of infected fish and water.

In addition to chemical contamination, improper disposal can lead to physical threats, such as oil spills, which need costly remediation initiatives. The lasting consequences of overlooking proper disposal practices extend beyond ecological deterioration, as neighborhoods may face financial difficulties as a result of reduced natural deposits and enhanced wellness care costs. Transformer Oil Purification. Attending to these dangers is vital for lasting ecological stewardship

Benefits of Specialist Recycling Services

Reliable administration of transformer oil with professional recycling solutions supplies various advantages that extend past mere conformity with ecological guidelines. Among the primary advantages is the decrease of ecological risks connected with incorrect disposal. By making use of specialized reusing processes, business can minimize the risk of soil and water contamination, therefore safeguarding ecosystems and public health.

Additionally, expert recycling solutions contribute substantially to resource conservation. Transformer oil can be refined and recycled, lessening the demand for brand-new oil production. This not just saves all-natural sources but also decreases energy usage and greenhouse gas emissions associated with oil removal and refining.

Moreover, engaging with professional services enhances operational efficiency. Organizations can simplify their waste administration processes, making sure that transformer oil is handled safely and properly. This can result in set you back financial savings in waste disposal and potential responsibilities connected to ecological damages.

The Recycling Refine Discussed

Using expert recycling solutions not just assists in decreasing environmental dangers and conserving resources yet likewise includes a systematic approach to the reusing procedure itself - Re-refining Transformer Oil. The recycling of transformer oil starts with the collection of made use of oil, which is frequently polluted with numerous pollutants, including dirt, water, and metal fragments

When accumulated, the oil undertakes a complete evaluation to identify its condition and the required therapies Your Domain Name required for reliable recycling. Next, the oil goes through purification and purification procedures, which might include vacuum distillation, clay treatment, and degasification. These techniques effectively remove impurities, bring back the oil to a functional state.

After filtration, the recycled transformer oil is evaluated to guarantee it meets market criteria and specs. By utilizing these precise actions, specialist reusing services make sure that transformer oil is recovered effectively, decreasing waste and promoting sustainable methods.

Choosing the Right Recycling Service Provider

Choosing the right recycling carrier for transformer oil is a crucial choice that can considerably impact both environmental sustainability and operational performance. When examining possible company, it is important to consider their accreditations and conformity with environmental regulations. A reputable recycler will comply with regional and national requirements, guaranteeing that the recycling procedure decreases ecological harm.

Furthermore, check out the service provider's experience and expertise in managing transformer oil. An established business with a tested track record will possess the required innovations and techniques to reuse oil successfully, preserving its top quality and reducing waste. Transparency in their procedures and willingness to share data concerning their recycling outcomes can additionally show a credible companion.

Expense is an essential aspect; however, it must not be the single factor. Analyze the overall worth provided by the company, including their solution reliability, client support, and the capacity for partnership in future sustainability initiatives. Lastly, look for endorsements or study from previous clients to determine their fulfillment. visit our website By carefully weighing these aspects, organizations can choose a recycling carrier that aligns with their ecological goals while making sure responsible and reliable administration of transformer oil waste.

Final Thought

In conclusion, the importance of dependable transformer oil reusing services can not be overemphasized. Eventually, the adoption of reliable transformer oil recycling techniques plays an find this essential role in promoting a lasting round economic climate and securing crucial ecosystems.

The usage of transformer oil, crucial for cooling and protecting electric transformers, leads to the buildup of waste oil that necessitates liable handling.By reusing transformer oil, firms can reduce their dependence on brand-new oil manufacturing, which is commonly resource-intensive and ecologically exhausting. By recycling oil, organizations can mitigate expenses linked with purchasing brand-new oil and managing waste disposal.Effective administration of transformer oil via specialist recycling solutions uses countless benefits that prolong past plain compliance with environmental regulations. Transformer oil can be fine-tuned and recycled, diminishing the demand for brand-new oil manufacturing.

Report this page